Can't take pic. If I pull them out it will drain 150 g of water on my hardwood floors. I will try to find a pic online for you

Announcement

Collapse

No announcement yet.

DYI duro pipes

Collapse

X

-

Thai, this is what I have in my 150. One on each side

Comment

-

Comment

-

So anyone know how to troubleshoot intermittent microbubbles coming out of the return line? Here are some details and things I've ruled out.....

- no microbubbles in the sump, i have a sponge in the baffle area and a prefilter sponge on the pump

- pump is completely submerged in water and pump fitting is sealed with teflon tape, all connections are secured by hose clamps

- loc-line return nozzle/fitting connected to the 45 degree elbow on the return pipe is also sealed with teflon tape where it connects

As I said the microbubbles are intermittent and not constant. A couple of things it could possibly be are that the 3/4" pvc isn't glued onto the 45 degree elbow where they slip into each other, neither is the connection of the 3/4" pvc and the bulkhead. That, or something to do with the mag pump itself. Other than that I have no idea.

Comment

-

-

if you want to get absolute silence, use flex hose on the line going from your durso down into the sump. approx. half way down the hose cut it and install a ball valve. you can then adjust the flow down to the sump. you don't have to match the flow from the return exactly, but the closer you get alot less air gets in the line and that is where all of the noise comes from.

if you are getting any girgling, chances are your air hole at the top of the durso is too big. lots of ways to fix that, from tape to toothpicks.

my tank is absolutly silent because I have a ball valve on my return and my overflow lines so once i get them equaled, i get no air in the line at all. it's a bit scarry at first becasue the water level is about 4 inches above the pipe in the overflow, but it's just a pipe, no durso at all. i cut the pipe about 5 inches from the top of the overflow so the "falling" water goes all of an inch.Softie Reef

Comment

-

I used this design for my 120G, works fine for me and the noise is not bad

Durso Standpipes are used to make your aquarium overflow (weir) nearly silent. We help you make your own or purchase them ready made!

Durso Standpipes are used to make your aquarium overflow (weir) nearly silent. We help you make your own or purchase them ready made!

rendered.jpg

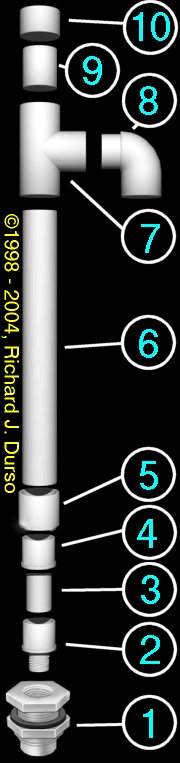

#10 - 1¼ PVC End-Cap with vent hole.

#9 - Connector made of 1¼ PVC. Glue to Tee, Teflon taped top for snug fit with End-Cap.

#8 - 1¼ PVC Street-Ell. Trim the connector for a compact design to help fit into smaller overflow chambers. Glued into Tee fitting. This is the water intake for the standpipe. Water level would be expected to be around the middle of this fitting.

#7 - 1¼ PVC Tee. Do not glue this onto the standpipe. Use Teflon tape on the standpipe for a snug fit. This allows it to be removed for height adjustment or maintenance.

#6 - 1¼ PVC Pipe. Sized long enough to get the End-Cap just about equal to the upper rim of the display tank.

#5 - 1¼ PVC Coupling. The stand pipe and reducer bushing are glued to this part.

#4 - 1¼ to 1 inch reducer bushing.

#3 - Connector made of 1 inch PVC. This should be glued into the reducer bushing. If you have a slip bulkhead, this inserts directly into the bulkhead — use Teflon tape for snug fit into the bulkhead.

#2 - OPTIONAL: 1 Inch PVC Male adapter - only needed on threaded bulkheads. You may want to attach to connector with Teflon tape to allow for a quick yank removal from bulkhead. Use Teflon tape on threads before inserting into bulkhead.

#1 - Bulkhead. The opening at the bottom of your overflow chamber to allow water to drain out to the sump. This drawing shows a threaded bulkhead.

Comment

-

-

Cool! Thanks for the tip.Originally posted by snookfish View Postif you want to get absolute silence, use flex hose on the line going from your durso down into the sump. approx. half way down the hose cut it and install a ball valve. you can then adjust the flow down to the sump. you don't have to match the flow from the return exactly, but the closer you get alot less air gets in the line and that is where all of the noise comes from.

How do you hook ball valves on a fix hose?

I don't see how you can connect them without leaks.I ate my fish that died.

Comment

-

i have a 1" ball valve, I cemented 1" pvc to each end, both peices being about 4" in length. I then fitted 1 1/4" flex tube over the 1" pvc and it is secured by a stainless steel collar (you screw it down to tighten it to ensure no leaks) . it's a tight fit when you put the flex tube over the pvc, the collar ensures nothing gets out.Softie Reef

Comment

Comment